Precast magnet – formwork magnet – a revolution in the prefabricated concrete market.

The refabricated concrete market as a percentage takes an insignificant part in the field of application of permanent magnets. Formwork magnet – what is it, type and characteristics, scope and rules of operation.

The refabricated concrete market as a percentage takes an insignificant part in the field of application of permanent magnets. Formwork magnet – what is it, type and characteristics, scope and rules of operation.

Precast magnet: the history of creation.

Innovation is the most profitable solution in the global economy. Suppliers in the construction market are aware of the demand for the use of permanent magnets. Especially for the production of precast concrete. And a cost-effective and efficient formwork solution needed. Previously, we worked with usual formwork which need welding, practice has shown that the solution is not profitable.

Terminology.

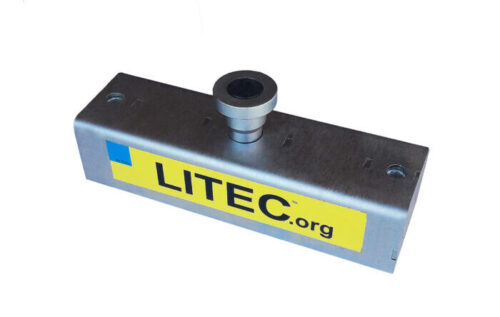

Precast magnet is a production tool made with permanent magnets and steel plates. In their production uses rare earth materials that provide high tensile strength.

Type and characteristics.

Appearance: steel box with a large button, when pressed, activates magnetic force. On top of the box, most often there are two thread holes. When equipped with different adapters, the functionality expands.

Specifications:

- t is possible to use both with wooden and steel formwork.

- Ease of use.

- Long service life.

- The range of magnetic force from 450 kg to 3 100 kg.

- The possibility of diverse applications.

- The maximum temperature for high-quality work is not higher than 80 degrees.

- Keeps the integrity and cleanliness of the shuttering shafts, no need to use bolts or welding.

- Possibility of individual order.

Hrecast magnet, whose technical indicators depend not only on the parameters, but also on the magnetic force (indicator in kg): 450, 650, 900, 1350, 1500, 1800, 2100, 2500, 3100.

Scope and rules of operation.

Widely used in the manufacture of walls from previously strained concrete panels. Allows to make any concrete slabs up to 60 cm high.

Important:

- The magnetic force can be reduced when a lot of iron or concrete dust gets between the magnet and steel table.

- Rust appears when the magnet is exposed to water for a long time, as well as reducing magnetic force.

- Shuttering magnet and negligence of workers leads to its failure.

Observing all the rules for using the prefab precast magnet will be able to hold the formwork even with strong vibrations.